8631-78267555

Industrial Zone of Botou, Cangzhou, Hebei, China

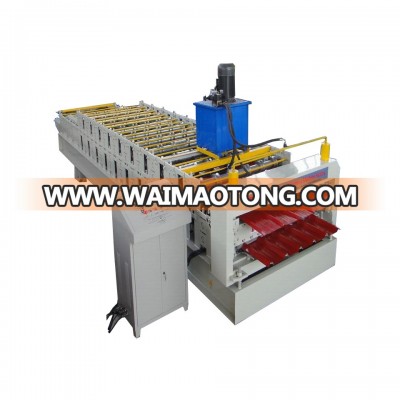

TR15 and TR30 Double Deck Roll Forming Machine, US $ 17,000 - 21,000 / Set, New, Tile Forming Machine, Colored Steel.Source from Botou Xianfa Roll Forming Machine Factory on Waimaotong.com.

Steel Step tile making machinery/glazed tile cold rolled forming machine

Hydraulic Double IBR panel roof /wall double deck roll forming machine

metal&zinc roofing sheet panel double deck roll forming machine

Building Material Wall Panel Metal Roofing Corrugated Tile Roll Forming Machine

XH EPS Sandwich Panel Double Layer Roof Sheet Roll Forming Machine